|

||

|

Meadowlark Audio

- Handmade in the USA |

||

|

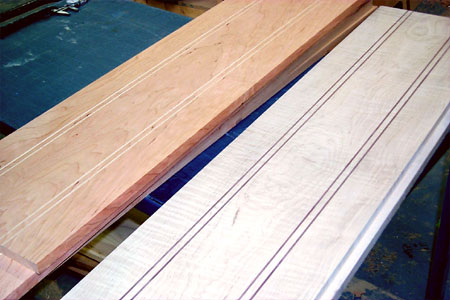

Here are the completed blanks ready to be machined into baffles by our CNC router. This operation is precise to within about 4 milli inches, or about the thickness of a sheet of paper. The process involves a series of operations done by numerous router bits spun at high rates of speed, but advanced through the wood in slow, iterative paths. |

||

|

|

||

|

The first operation is the engraving of our logo! Then, as Michelangelo put it, we remove all of the material that is not the sculpture, in this case the baffle. Each Blue Heron 2 baffle takes nearly an hour of machine time to complete.

|

||

| Back Next | ||

It's big and it's dumb but it does what it's told.

It's big and it's dumb but it does what it's told.