|

|

|

|

|

|

|

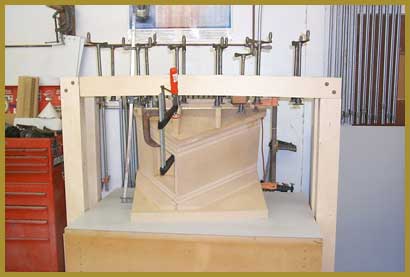

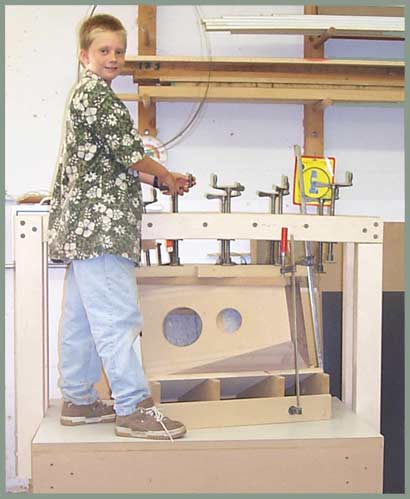

The unusual shape of the Nightingale 'head' unit has presented a real challenge when it comes to applying the veneer. Two large facets meet at an oblique angle, at which the veneer must make a tricky bend. The solution, as seen here, is a dedicated set of presses: one for right sides and a mirror image device for left sides. |

|

The head unit is held in a special cradle that presents it at the correct angle to the press. An articulated 'butterfly' press and batten assembly assures a tight, even fit and uniform distribution of force. |

|

|

|

Since a great deal of effort has already gone into each head unit by the time it is ready to be veneered, and because this operation requires absolute precision, great care is taken at every step. |

|

Here, Beau Carpenter, who often works with his dad Carl, releases the torque on the veneer press screws in anticipation of removing the head from the press. This pair is headed to Alternative Audio's fabulous new store in Dundas Canada. If you can get the chance, please stop by and give 'em a listen. |